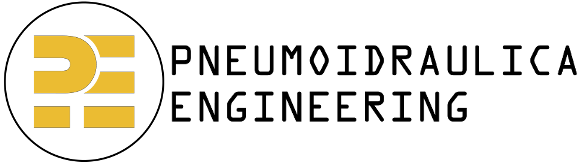

Wellhead control panels (WHCP)

PNEUMOIDRAULICA ENGINEERING designs, manufactures and installs many kind of wellhead control panels (WHCP) necessary for the safety of the stockage and production wells in Oil & Gas field.

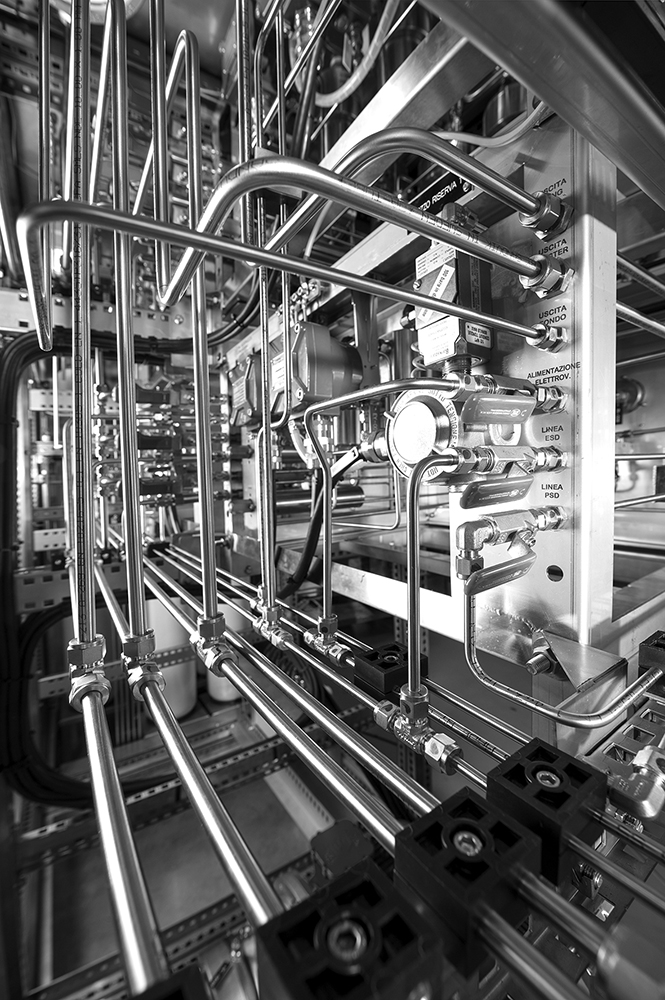

The WHCP are integrated systems that, within a single cabinet, collect the electrical, pneumatic and hydraulic circuits necessary for the control of all the valves placed in the wellheads (SCSSV, master, wing) and other safety valves (choke, ESD, HIPPS). The hydraulic power can be generated through the pumps driven by an electric motor or pneumatically driven, also using directly the gas coming from the well. The electric circuit for the management of the interfaces with the supervision system (DCS / SCADA), the hydraulic accumulators and the oil tanks are placed inside the cabinet, in separated sections. Those systems may be assembled in the “single well” version or in the “multi-well” with extractable drawers to facilitate the maintenance operations.

Standard features:

- Components layout carefully studied to facilitate the control, checking and maintenance operations

- Executions in AISI316 stainless steel (even varnished)

- Maximum pressure 690 bar (10,000 PSI)

- Circuits with different pressures (H.P. for SCSSV, M.P. for master, wing, choke, ESD, HIPPS, L.P for logic)

- Double ferrule compression fittings

- Imperial or Inch Tubing (according to ASTM A-269)

- Working through gas or eletcric pumps (Vac o Vdc) + manual pump for emergency

- Hydro-pneumatic accumulators (bladder-type or piston) to ensure emergency manoeuvres even in case of power failure

- Oil tank with flame arrester, capacity up to 3,000 litres

- Collection tank (drip pan) for the recovery of accidental losses

- Local and remote control via interface with PLC / DCS / SCADA / RTU

- Fusible plugs network management (pneumatic or hydraulic)

- Manual, pneumatic, hydraulic, electric ESD (emergency shut-down)

- Flowline control by pressure pilots PSL/PSH (garrett)

- Manual, pneumatic, hydraulic, electric PSD (process shut-down)

- Protection of each line by “Thermal relief valve”

- Safety components in SIL2 grade according to IEC 61508:2010

- Nameplates and documentation in Italian or English

- Certification according to PED / ASME / ATEX / IECEx

Special features:

- Very low power consumption for use with photovoltaic panels (green technology)

- Installation in severe climate conditions (very low/very high temperatures, desert zones, etc.)

- Cabinet IP65

- Shut-down with “first out” system

- Hydraulic fluids water / glycol based

- Separated Skids for accumulators (also equipped with booster for nitrogen charging in high pressure)

- Pressure up to 1,379 bar (20,000 PSI)

- Fittings with ferrule screwed on the conical tube

- Application in presence of H2S (NACE MR01-75)

- Nameplates and documentation in different languages (Russian, Arabic, etc.)

- Executions according to Norsok or other international Standards

- Testing Officiated and Certification on customer request

- Safety components in SIL 3 grade according to IEC 61508:2010