Dryers – Nitrogen generators

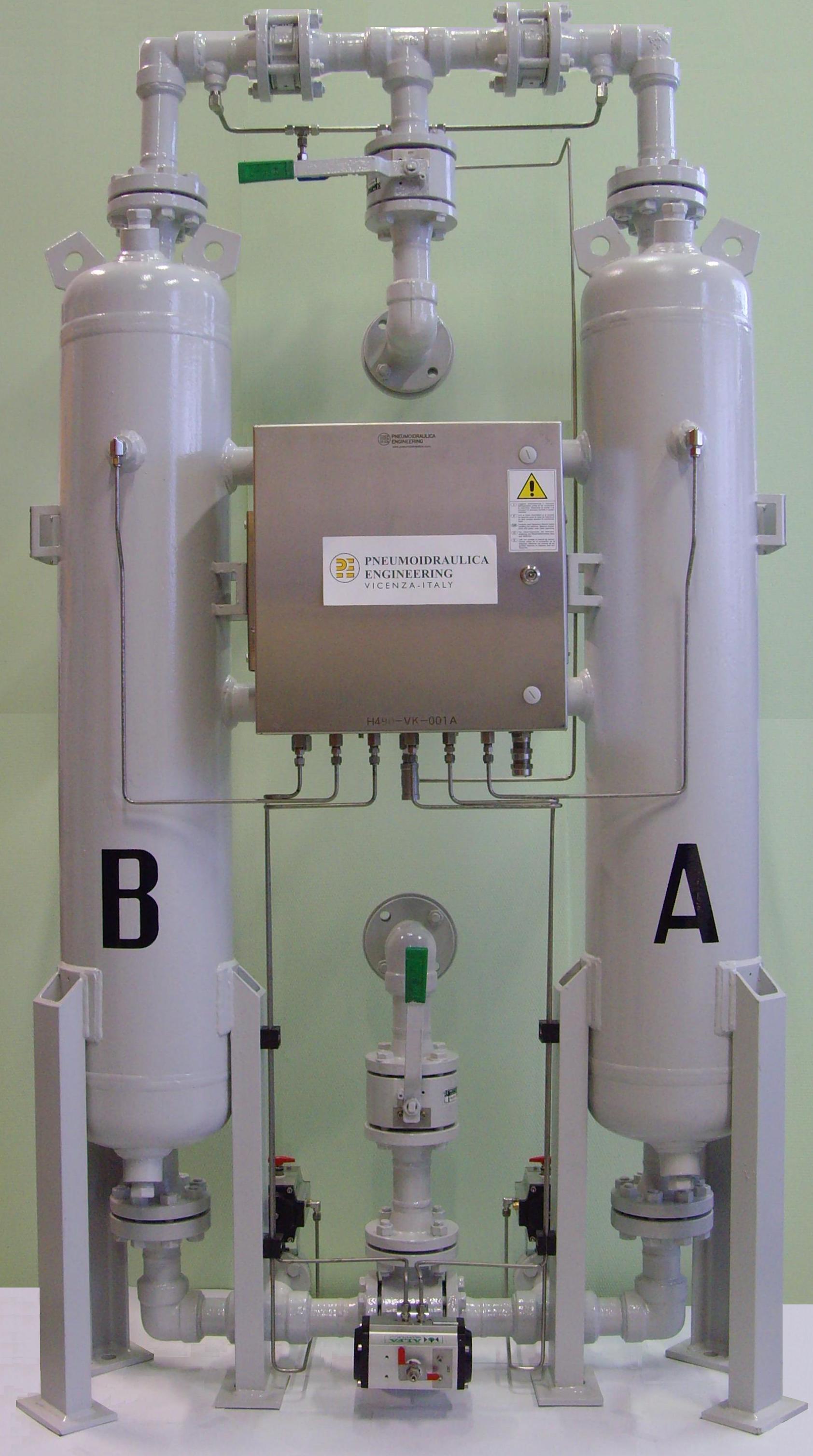

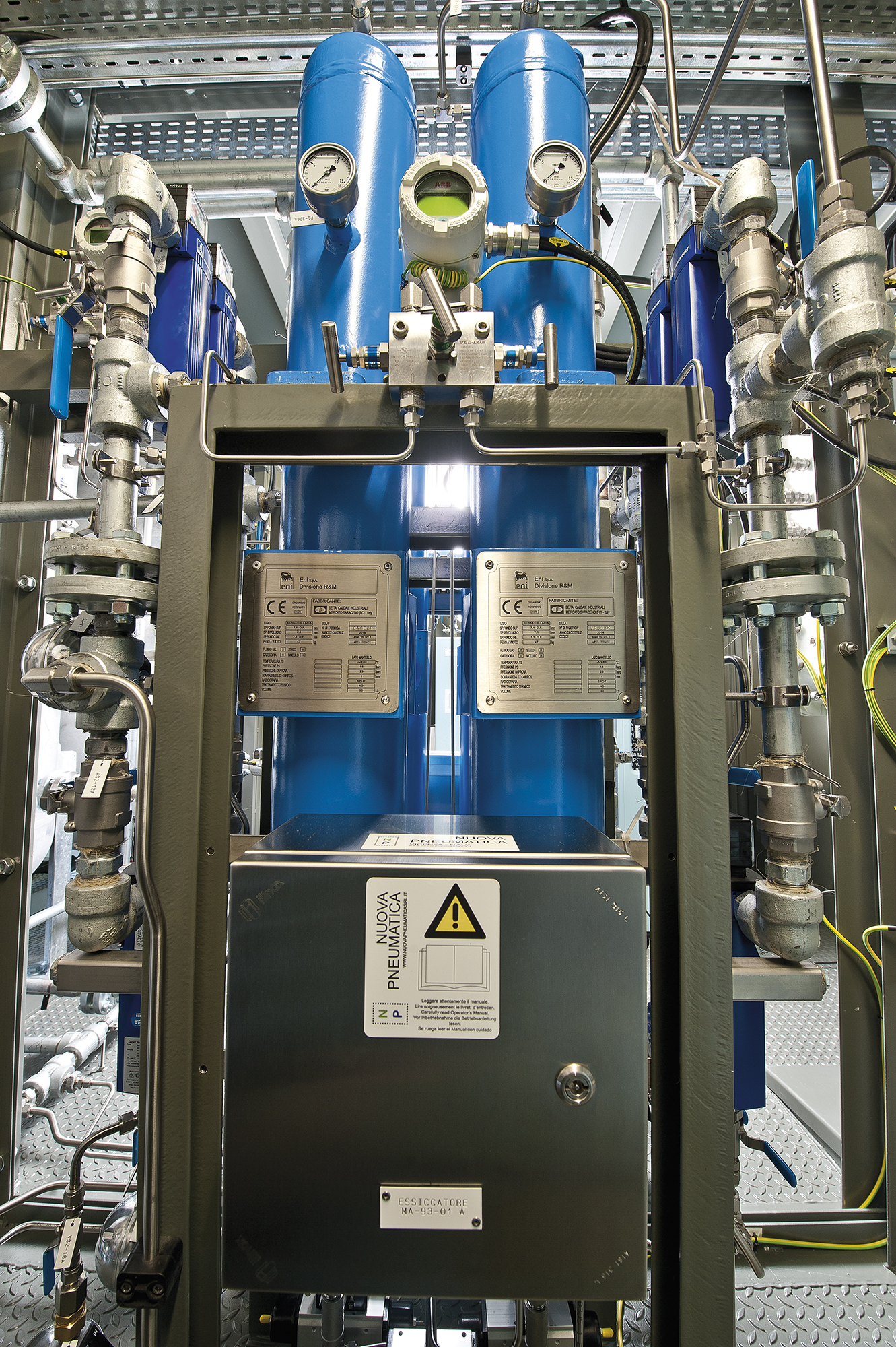

PNEUMOIDRAULICA ENGINEERING, through the partner company NUOVA PNEUMATICA, designs and

manufactures custom-made dryers and vacuum generators. The typical execution includes the installation on “skid” with pre-filtration and post-filtration system. The fields of application are numerous: Oil & Gas, chemical, pharmaceutical, industrial, etc. in potentially explosive areas ( ATEX ).

Features of the dryers:

- Technology: adsorption with molecular sieves without heat (heatless) / diaphragm

- Fluid: compressed air, inert gases, flammable gases

- Working pressure up to 200 bar

- Varnished carbon steel / AISI316 stainless steel

- Control logic: pneumatic with fixed cycles / electronic with variable cycles

- Dew point: up to -70°C

- Dew point transmitter with programmable alarm thresholds

- Certification according to CE87/404 – 2014/68/UE (PED) – 2014/34/UE (ATEX) - ASME

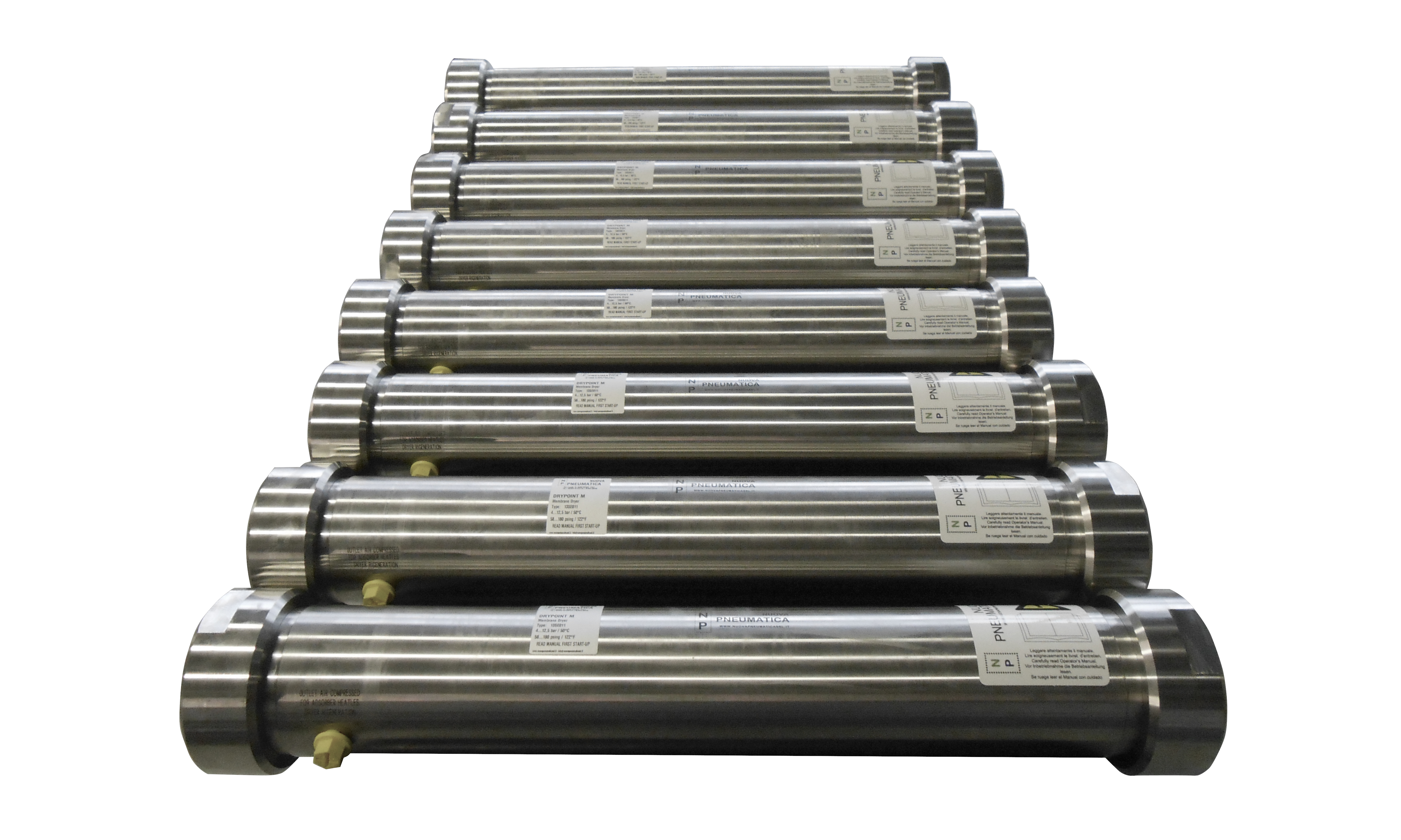

Features of the vacuum generators:

- Technology: PSA with molecular sieves / diaphragm

- Working pressure up to 300 bar (through booster)

- Varnished carbon steel / AISI316 stainless steel

- Control logic: electronic with variable cycles

- Purity degree: up to 99,9%

- Purity transmitter with programmable alarm thresholds

- Certification according to CE87/404 – 2014/68/UE (PED) – 2014/34/UE (ATEX) - ASME

Special features:

- ASME VIII div.1 – “U” stamp

- Instrument air production according to ISO 8573-1

- Diaphragms in Aluminium, AISI316L, AISI904, Duplex, Super Duplex.

- Redundant versions (base / stand-by) with manual or automatic switch

- Installation in severe climate conditions (very low/very high temperatures, desert zones, etc.)

- Testing Officiated and Certification on customer request

- Nameplates and documentation in different languages (Russian, Arabic, etc.)