Sampling

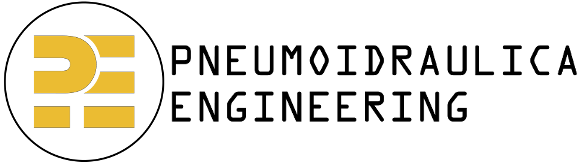

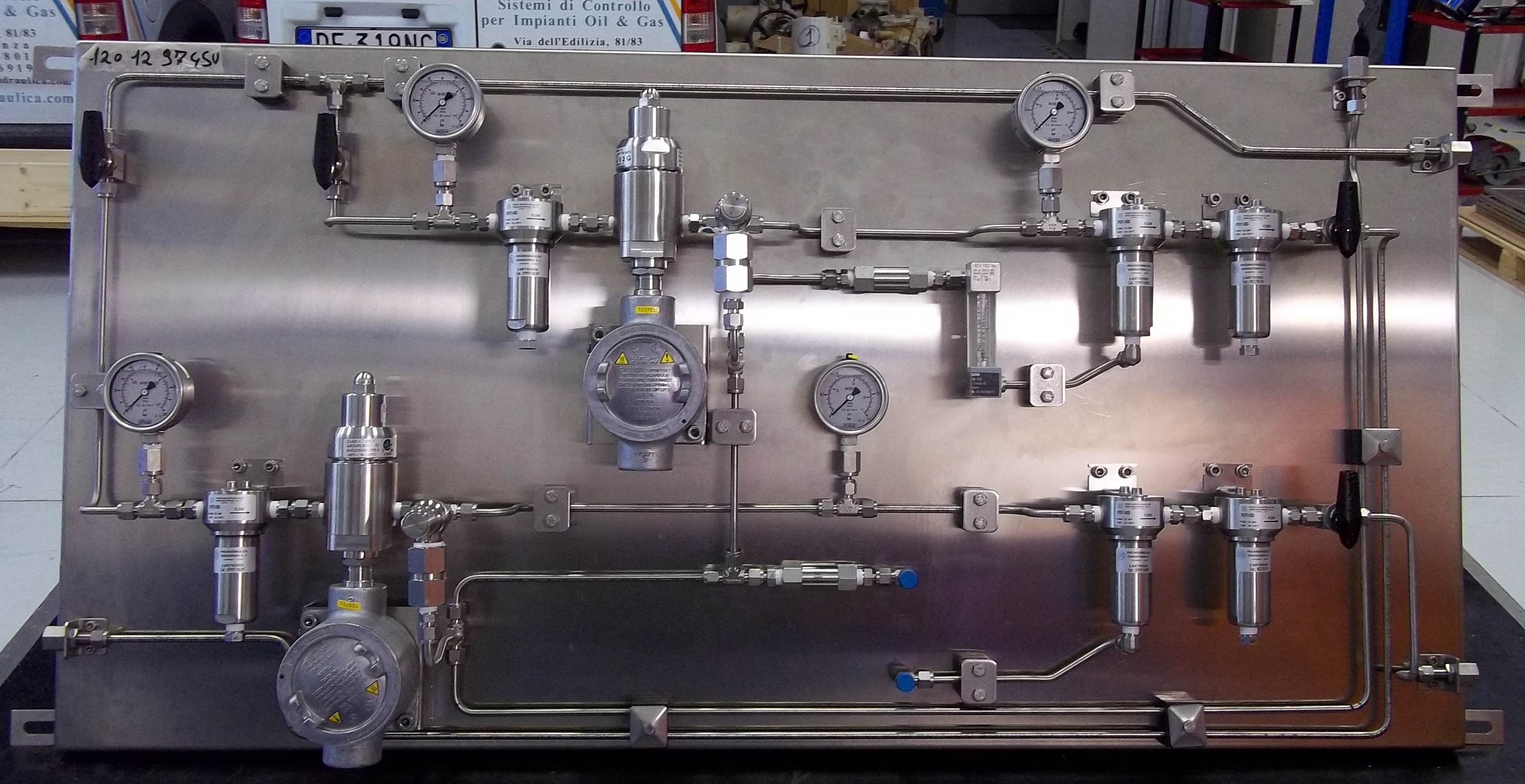

PNEUMOIDRAULICA ENGINEERING designs and manufactures many kinds of sampling systems for Oil & Gas (Production, storage plants, refineries, etc.). Those systems, through a suction circuit, take the gas to be analyzed and they send it, after appropriate treatments (filtration, pressure reduction, temperature control), to the analysis tools that verify their chemical / physical features.

The most common application is to take the hydrocarbon from the production plant to send it to the cab of analysis in order to obtain, in continuous, the chemical composition and the energy values of the same. In absence of the cab of analysis the system provides for a sampling cylinder (approved for the transport of hazardous fluids) allowing the operator to collect manually the sample to be sent to the laboratory in a total safety. It is also available an automatic system totally pneumatically operated for the sampling of the non-gaseous products.

Standard features:

- Components layout carefully studied to facilitate the control, checking and maintenance operations

- 6 ways special valve for the sampling / washing switching

- Execution in AISI316 stainless steel (even varnished)

- Arrangement in cabinet IP55

- Max. pressure 420 bar (6,000 PSI)

- Double ferrule compression fittings

- Imperial or Inch Tubing (according to ASTM A-269)

- Sampling cylinders according to T-PED / DOT rules

- Nameplates and documentation in Italian or English

- Certification according to PED / ASME / ATEX / IECEx

Special features:

- Installation in severe climate conditions (very low/very high temperatures, desert zones, etc.)

- Cabinet IP65

- Pressure up to 1,379 bar (20,000 PSI)

- Fittings with ferrule screwed on a conical tube

- Fittings and tubing in PTFE/PVDF/6Mo/904L/Monel/Hastelloy

- Sampling cylinders with internal lining

- Applications in presence of H2S (NACE MR01-75)

- Nameplates and documentation in different languages (Russian, Arabic, etc.)

- Executions according to Rules Norsok / UL or other international Standards

- Testing Officiated and Certification on customer request

- Automatic sampler equipped with pneumatic control panel (adjustable number and times of cycles)