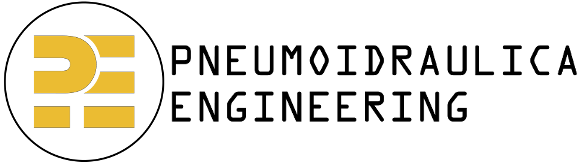

Actuators control

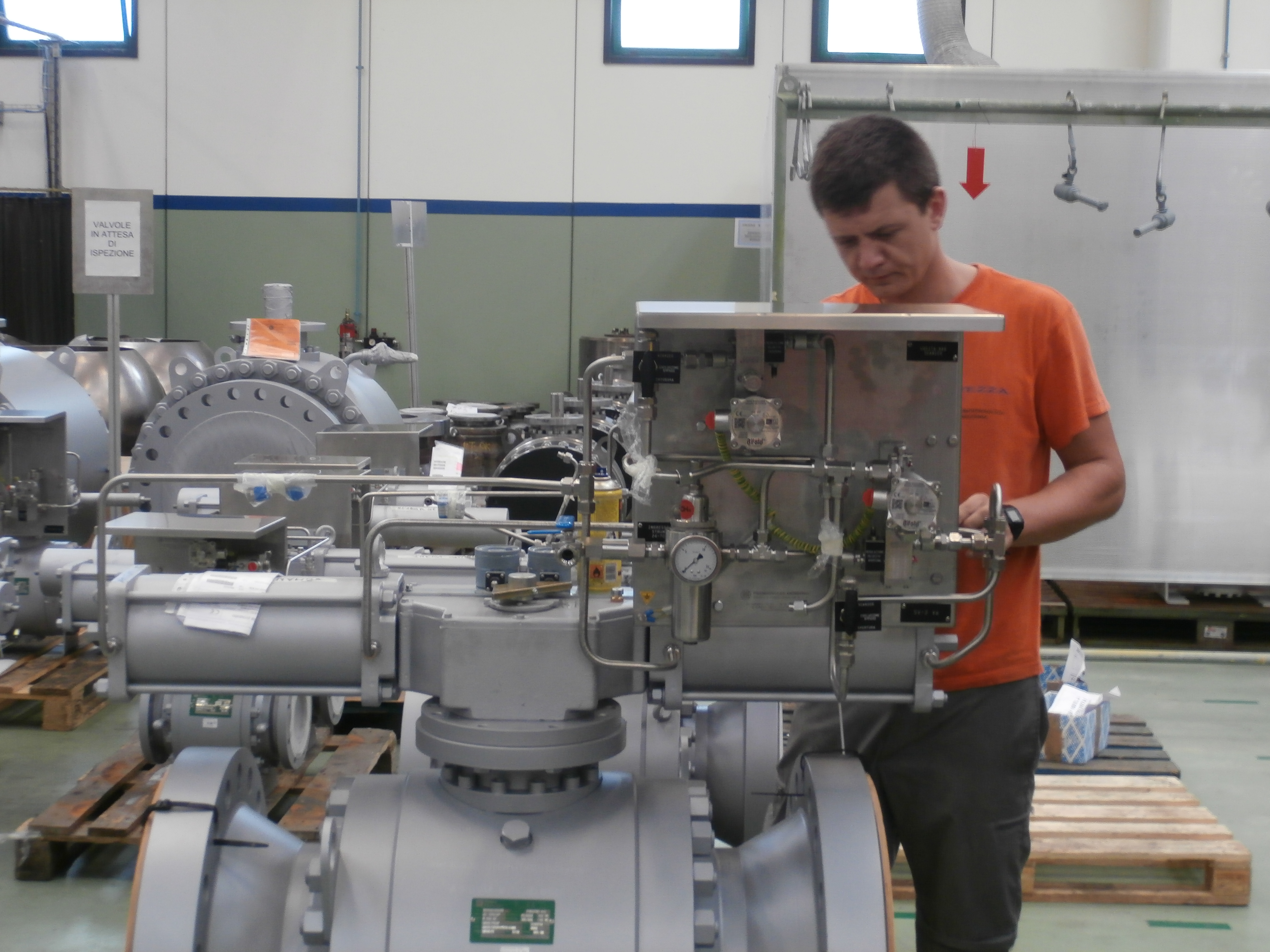

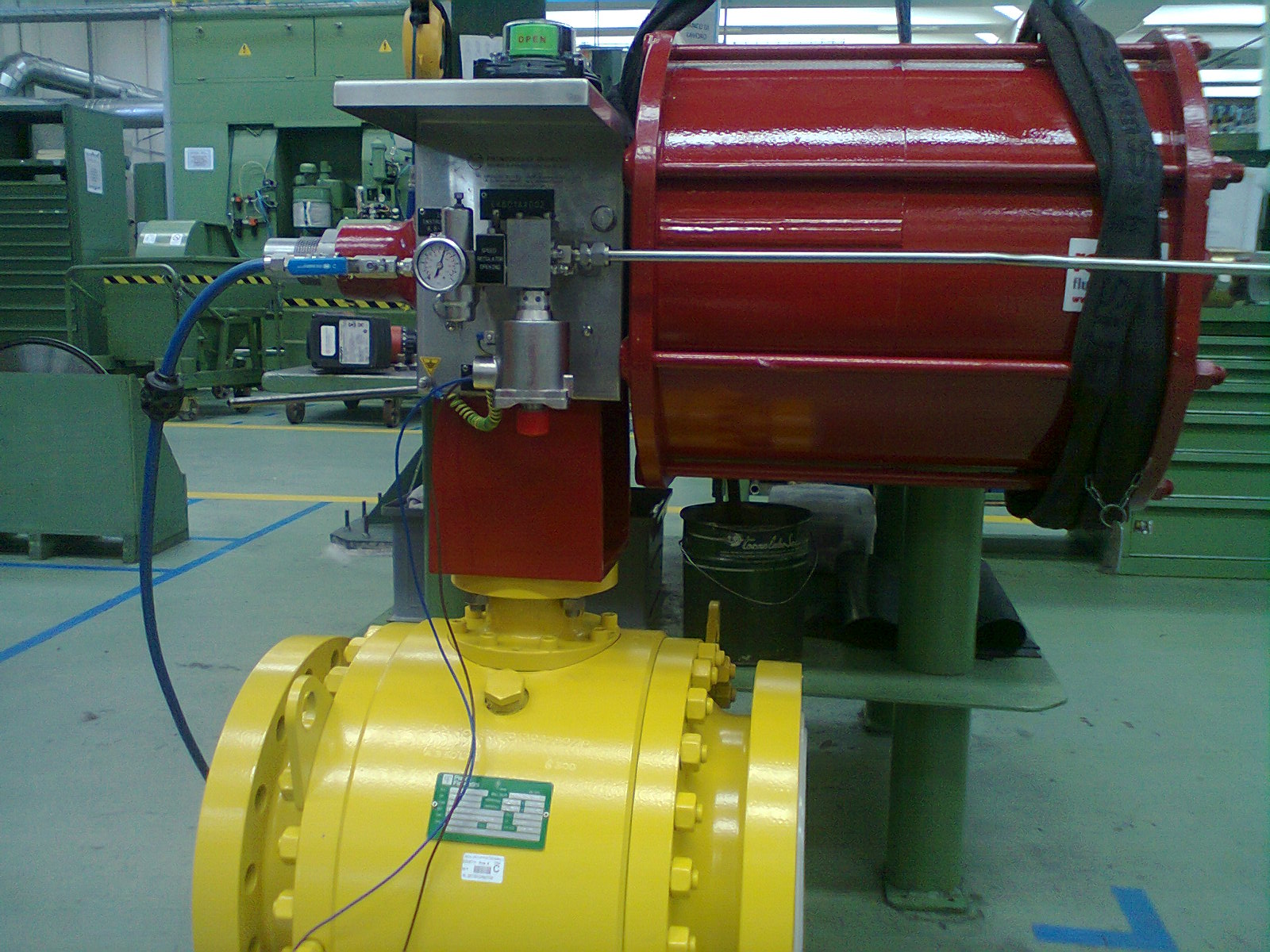

PNEUMOIDRAULICA ENGINEERING designs, manufactures and installs many kinds of actuator control systems, pneumatic or hydraulic, for the normal operation and the safety of the plants in Oil & Gas field. Those systems are equipped with electric, pneumatic and hydraulic circuits suitable for the control of the actuators moving the relevant valves. The control can be of on/off type (open/close) or proportional based on the signal received from the control room (pneumatic or electric). It is also available a system with “Partial Stroke” test device, manual or automatic, for application in HIPPS systems.

Standard features:

- Components layout carefully studied to facilitate the control, checking and maintenance operations

- Executions in AISI316 stainless steel (even varnished)

- Arrangement in cabinet IP55 or on plate at sight

- Maximum pressure 420 bar (6,000 PSI)

- Double ferrule compression fittings

- Imperial or Inch Tubing (according to ASTM A-269)

- Hydro-pneumatic accumulators (bladder-type or piston) or pneumatic tanks to ensure emergency manoeuvres even in case of main power failure

- Local and remote control via interface with PCL / DCS / SCADA / RTU

- EEx-ia / EEx-d executions

- Fusible plugs network management (pneumatic or hydraulic)

- Manual, pneumatic, hydraulic, electric ESD (Emergency Shut-Down)

- Manual, pneumatic, hydraulic, electric PSD (Process Shut-Down)

- Safety components in SIL2 grade according to IEC 61508:2010

- Nameplates and documentation in Italian or English

- Certification according to PED / ASME / ATEX / IECEx

Special features:

- Media: Nitrogen

- Very low power consumption for use with photovoltaic panels (green technology)

- Installation in severe climate conditions (very low/very high temperatures, desert zones, etc.)

- Cabinet IP65

- Manual or automatic “partial stroke” device

- ≤ 3 seconds operation time (for HIPPS valves)

- Compatibility with hydraulic fluids water / glycol based

- Separated skids for accumulators / tanks

- Pressure up to 690 bar (10,000 PSI)

- Application in presence of H2S (NACE MR01-75)

- Nameplates and documentation in different languages (Russian, Arabic, etc.)

- Executions according to Rules Norsok

- Testing Officiated and Certification on customer request

- Safety components in SIL3 grade accoding to IEC61508:2010